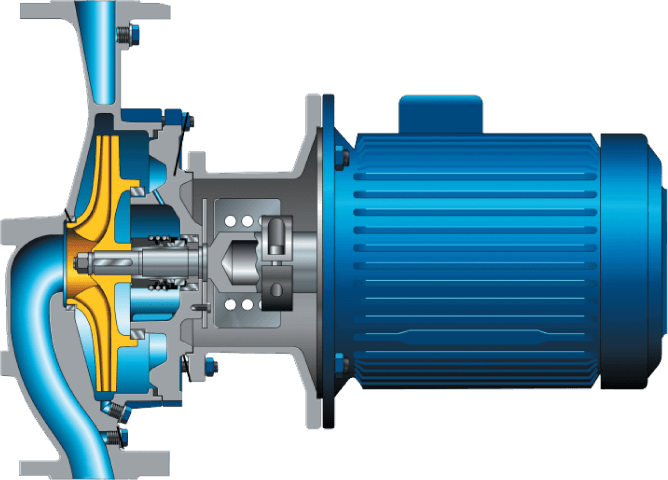

Vertical Inline Pump

Etaline

In the Vertical Inline Pumps, the inlet and outlet are inline. This arrangement is

typically used where space is limited such as onboard a ship, Generator Jacket

Cooling etc. This type of pumps can be made to various designs which include spacer

couplings to enable maintenance to be carried out without removal of motors

reducing downtime. In monobloc designs, an inline pump will usually have a single

shaft connecting the motor to the pump head meaning the motor bearings bear the

full rotary load of the shaft during operation. This design of pump is better suited for

short duties at full motor speed, and light duties. During maintenance the motor and

pump must be disassembled with the mechanical seal refitted at the same time as

motor fitting.

Fluid to be Handled

Clean & Clear Water

Connection Type

Flange

Drive Connect with

Electric Motor

Casing Material

Grey Cast Iron

Impeller Material

Grey Cast Iron

Shaft Material

Tempering Steel C 45 / SS 1.4462

Shaft Seal Type

Mechanical Seal

Pump Type

Monobloc

Suction Behavior

Non Self-Priming

Max. Flow rate

400 m3/h

Min. Flow rate

2 m3/h

Max Head

102 M

Min Head

2 M

Max. Casing Pressure

16 bar

Max. Allowed Fluid Temperature

140 °C

Min. Allowed Fluid Temperature

-30 °C

Mains Frequency

50 Hz.

Mains Voltage

220 V / 440 V

Generator Coolant Circulation

Air-Conditioning Systems

Cooling Circuits

Heating Systems

Water Supply

Industrial Recirculation Systems

Heat Recovery Systems

Service Water Supply Systems