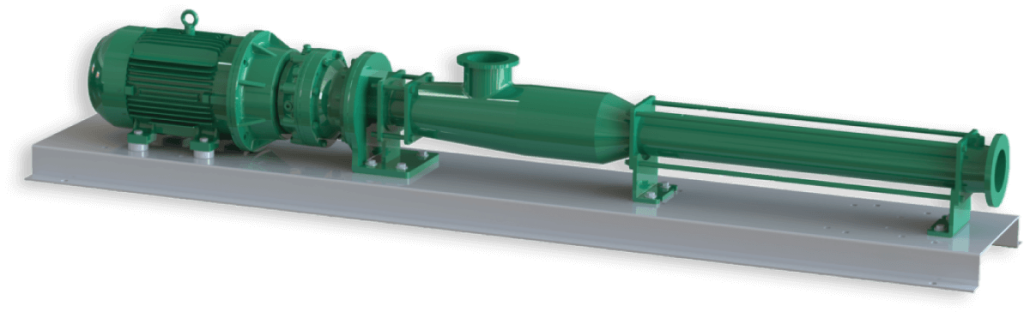

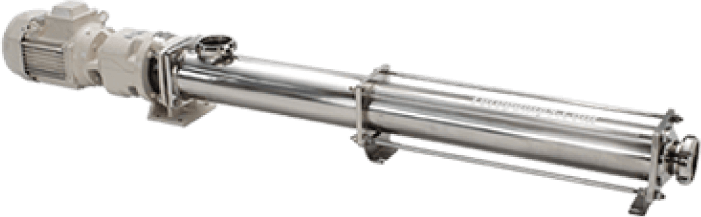

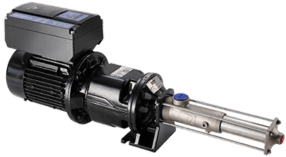

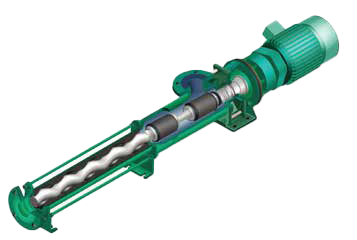

Progressive Cavity Pump

RM/RD/RL

One of the most dynamic designs for driving the flow of variety of liquids, Progressive Cavity Pumps can be customized to efficiently handle liquids with different viscosity levels and chemical properties. The Progressive Cavity Pumps comprise of a precision mechanized single external helix metallic rotor and double internal helix elastomer stator. As the rotor turns within stators, the cavity progresses from suction to discharge along with fluid. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions. As the rotor turns within the stator, these cavities progress from the suction to the discharge end of the pump carrying the fluid. So that it can transfer high viscous liquid with solid particle up to 3,000,000 cST.

Positive Displacement

Because of single rotating element, progressive cavities are generated which deliver a uniform, metered and Positive Displacement flow.

Self Priming

Inherently self-priming, the pumps can work on snore and do not require a foot valve.

Non-Clogging

Can handle solid in suspension or media containing a high percentage of solids.

Low NPSH Requirement

Suction lift capabilities of up to 9.5 mwc and effective in high vacuum conditions.

Low Internal Velocity

Minimum degradation of shear-sensitive media, and can also handle highly viscous materials having pseudo-plastic characteristics.

Reversible

Due to the reversible rotation capabilities, Progressive Cavity Pumps can perform with equal efficiency in either direction.

Silent Running

Rotors turn inside a resilient stator and thus generate little noise.

Separate Bearing Housing

Fluids can be pumped without no contamination.