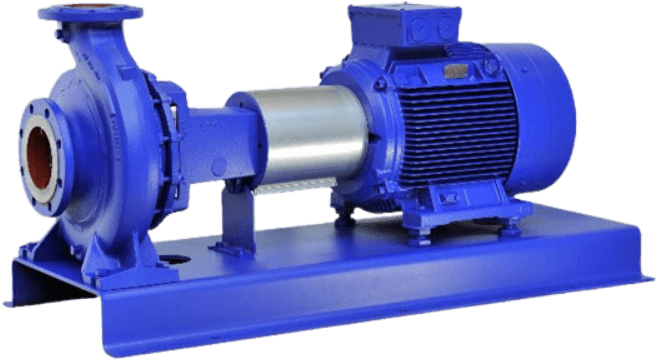

Centrifugal Pump

Etanorm

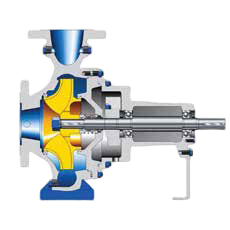

Horizontal volute casing pump, single stage with power ratings and main dimensions to EN 733 up to DN 200 with bearing bracket, in back pull out design. Back pull-out design helps to dismantle the pump keeping the casing in the pipe line. Shaft with replaceable shaft sleeve / shaft protecting sleeve in the shaft seal area. Volute casing and impeller with replaceable wear rings. Volute casing with integrally cast pump feet. Pump is incorporated with grease lubricated robust deep-groove ball bearing and mechanical seal to EN 12756 or gland packing. The efficient operation of a centrifugal pump relies on the constant, high speed rotation of its impeller. With high viscosity feeds, centrifugal pumps become increasingly inefficient: there is greater resistance and a higher pressure is needed to maintain a specific flow rate. In general, centrifu-gal pumps are therefore suited to high capacity pumping applications of liquids with viscosities between 0.1 and 200 cP. This pump is suitable for Handling clean and clear fluids not chemically and mechanically aggressive to the pump materials.

Fluid to be Handled

Clean & Clear Water

Connection Type

Flange

Drive Connect with

Motor / Combustion Engine

Casing Material

Grey cast iron JL 1040 / SS 316 (CF8M)

Impeller Material

Grey cast iron JL 1040 / SS 316 (CF8M)

Shaft Material

Tempering Steel C 45 / SS 1.4462

Bearing Bracket

Grey cast iron JL 1040

Shaft Seal Type

Mechanical Seal / Gland Packing

Suction Behavior

Non Self-Priming

Max. Flow rate

660 m3/h

Min. Flow rate

1.5 m3/h

Max Head

160 M

Min Head

2 M

Max. Allowed Working Pressure

16 bar

Max. Allowed Fluid Temperature

120 °C

Min. Allowed Fluid Temperature

-30 °C

Mains Frequency

50 Hz.

Mains Voltage

220 V / 440 V

Water supply systems

Cooling circuits

Swimming pools

Fire-fighting systems

Irrigation systems

Drainage systems

Heating systems

Air-conditioning systems