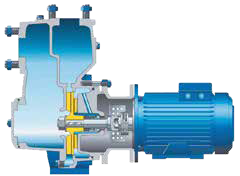

Self Priming Centrifugal Pump

SPnorm

In normal condition, common centrifugal pumps are unable to evacuate the air from an inlet line leading to a fluid level whose geodetic altitude is below that of the pump. Self-priming pumps have to be capable of evacuating air from the pump suction line without any external auxiliary devices. Centrifugal pumps which are not designed with an internal or external self-priming stage can only start to pump the fluid after the pump has initially been primed with the fluid. In addition, a suction-side swing check valve or a vent valve must be fitted to prevent any siphon action and ensure that the fluid remains in the casing when the pump has been stopped. In self-priming centrifugal pumps with a separation chamber the fluid pumped and the entrained air bubbles are pumped into the separation chamber by the impeller action

Fluid to be Handled

Muddy Water, Sewage, Polluted Liquid

Connection Type

Flange

Drive Connect with

Motor / Combustion Engine

Casing Material

Grey Cast Iron

Impeller Material

Grey Cast Iron

Shaft Material

Tempering Steel C 45 / SS 1.4462

Shaft Seal Type

Mechanical Seal / Gland Packing

Pump Type

Bare Shaft / Monobloc

Suction Behavior

Self-Priming

Max. Flow rate

253 m3/h

Min. Flow rate

1.5 m3/h

Max Head

50 M

Min Head

2 M

Max. Allowed Fluid Temperature

140 °C

Min. Allowed Fluid Temperature

-30 °C

Mains Frequency

50 Hz.

Mains Voltage

220 V / 440 V

Bearing Bracket

Grey Cast Iron

Industrial : Pumping Petroleum Products, Chemicals, Effluents, Sewage, Ash-Water Etc

Tiles & Marble industry : For Handling Waste Water.

Civil Construction : De-Watering Foundation, Trenches and Pits.

Public Utilities : Sewage Pumping.